Tackling tough challenges in high tech digital transformation

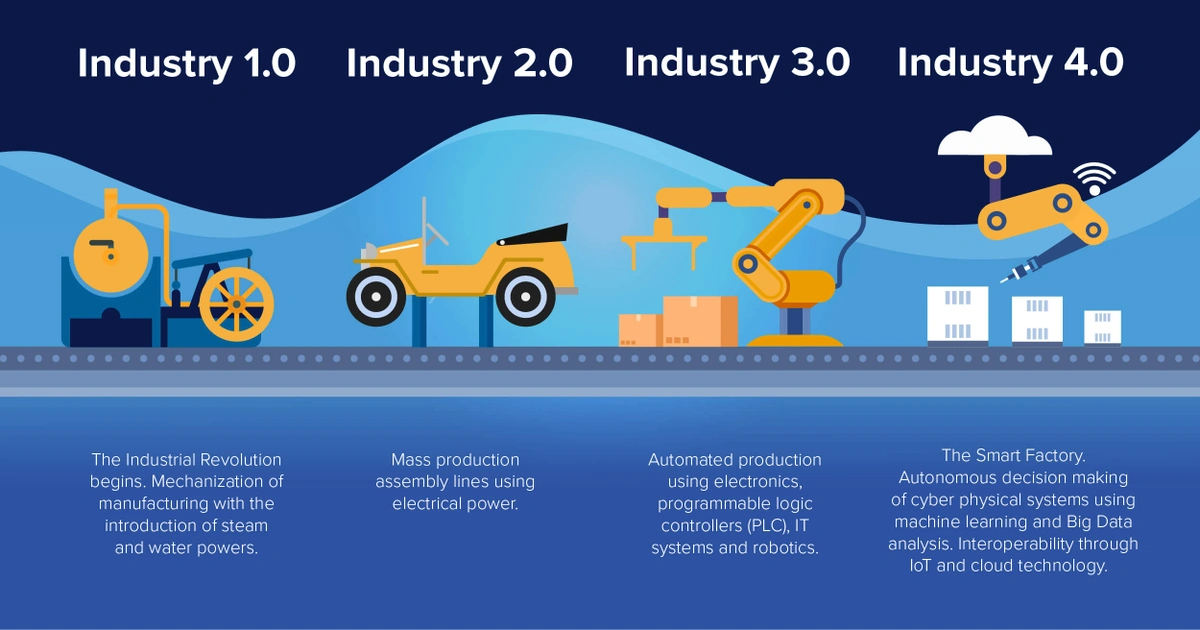

It’s been dubbed “The Fourth Industrial Revolution” or 4IR for short. And some refer to it as “digital transformation.”

What exactly is Industry 4.0 and is it really a revolution?

Or is it more of a transformation – and a lengthy one at that? Should high tech manufacturers be overly concerned about being left behind?

Let’s start by looking back.

High tech digital transformation within manufacturing is nothing new or even necessarily revolutionary. It’s the progressive evolution of technology that’s been going on for several decades – hardly a revolution. What we are witnessing now, just like with the previous “industrial revolutions,” is the result of years of steady and progressive innovation coming to fruition.

– Daniel Burrus, Bestselling author and tech innovator

Industry 4.0 involves the emergence and rapidly increasing use of digital technologies such as artificial intelligence, additive manufacturing, augmented reality, cloud, big data and the ubiquitous Internet of Things. Digitally-enabled processes have now progressed to the point where they have become much more capable, scalable, efficient and cost effective.

When the disruptor becomes the disruptee

As a high tech company, you face many challenges when it comes to innovation. Chief among them is the competitive landscape dictating the need to be an innovation disruptor. Even for high tech innovators like you, the past several years have wreaked havoc on your manufacturing and chances are, you’ve become the disruptee, not the disruptor.

Many high tech companies are still struggling to rebound from the pandemic shutdowns, lows in manufacturing staffing and of course, the ongoing supply chain disruption. Eliminating legacy processes and investing in technology is an added pressure. While your company might be grappling with how Industry 4.0 will impact your business or how to overcome the lack in knowledge and talent to best adopt it for your ecosystem, chances are your competitors are steps ahead paving the way for their future. As a result, smart manufacturing is no longer an option to consider for any high tech company but rather an essential requirement to innovation.

Drive the thinking forward

It’s imperative that you plan now to drive your company’s thinking forward and solve the challenges you face in the high tech industry whether it’s overcoming supply chain disruption or innovating supply chain operations, go-to-market operations, or factory challenges, realizing your digital future starts now.

Industry 4.0 impacts every team in your company. Data is fast becoming a focal point. Advancing end-to-end transformation across your entire company ecosystem with 360° visibility and greater viability — that’s high tech Industry 4.0 for manufacturing well beyond the factory floor.

The focal point in your strategy is in knowing how to take advantage of all the benefits that Industry 4.0 technology has to offer – without the marketing hype. There are many digital-based solutions available today to high tech companies that are fairly easy to implement, offer a good return on investment, and don’t require a major upheaval of your existing operation — as has been the case in the industry for many years.

It’s important not to overlook your go-to-market revenue generating processes. These processes have been transformed by digitalization too. This is an area in which you can realize some definite gains in both efficiency and error reduction. For example, many high tech manufacturers still rely on spreadsheets to track their incentive rebate and ship and debit processes. In addition to being very inefficient, this practice is prone to errors related to data collection and data entry. It’s not a very “Industry 4.0” based process. This can be analogous to a manufacturing technique known as error-proofing. The goal is to prevent a given task or process from being performed incorrectly such as inserting a part into a machine the wrong way. The objective is to minimize (or ideally eliminate) the chances of making such an error.

The fundamental intent of Industry 4.0 is to make manufacturing – and all company teams faster, more efficient and customer-centric, while at the same time utilizing end-to-end automation to view data and analytics uncovering new business opportunities and models.

The role that digital technology plays in manufacturing is becoming more and more apparent. The key is in learning how to take advantage of all the benefits that the technology has to offer – without getting overly concerned about the exaggeration and marketing hype. It’s important to keep in mind that the high tech industry and the technologies that enable it have always been in a constant state of growth. Industry 4.0 is an evolving strategy with process as opposed to an event. It’s not a revolution. Become your own best expert and determine what makes sense for your organization.